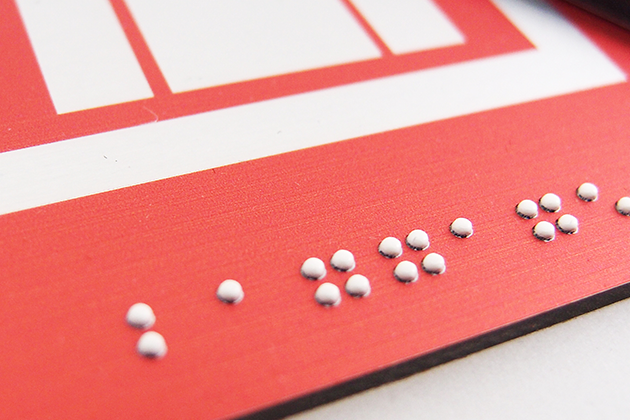

Texture Printing Effect

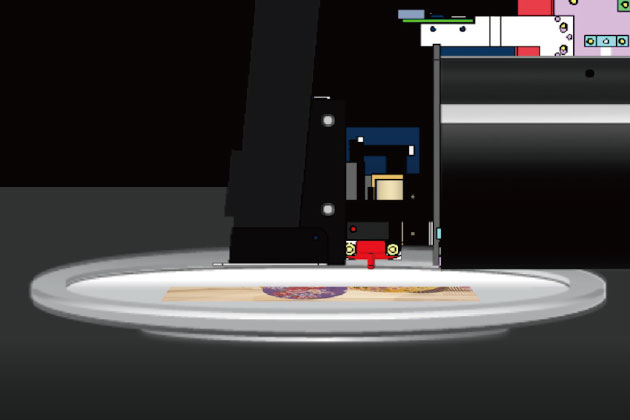

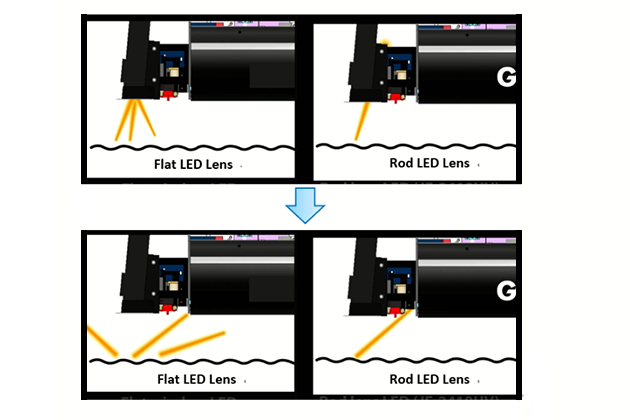

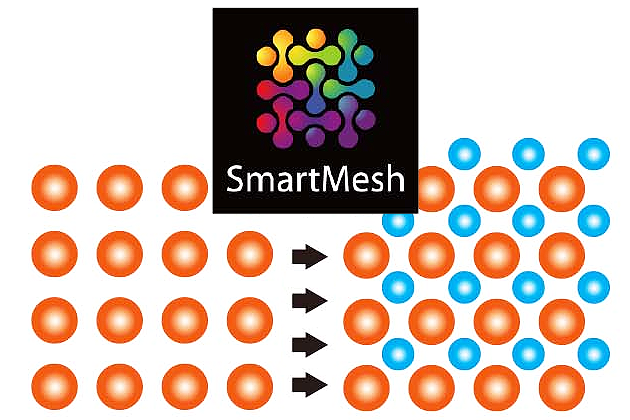

JF-2418UV is a convenient tool for anyone to create raised pattern and provide added value to RFID, boutique goods and jewelry, oil painting reproduction and so on.Moreover, the high resolution printing ability delivers refined output—even 2pt small letters can be printed with high sharpness and definition in sophisticated details to serve a diversity of applications.