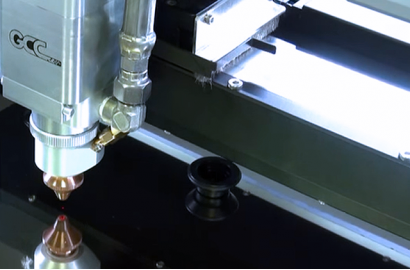

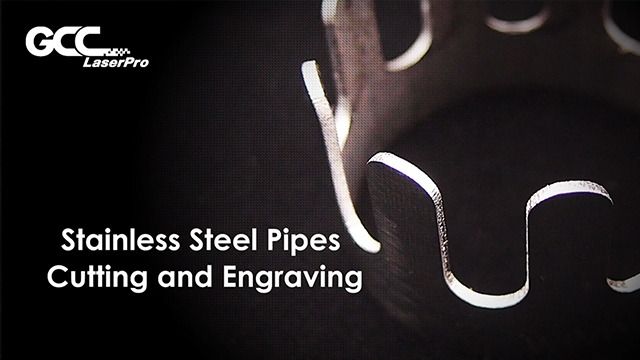

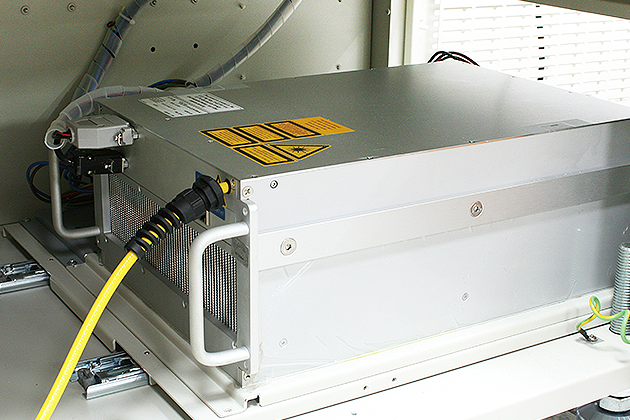

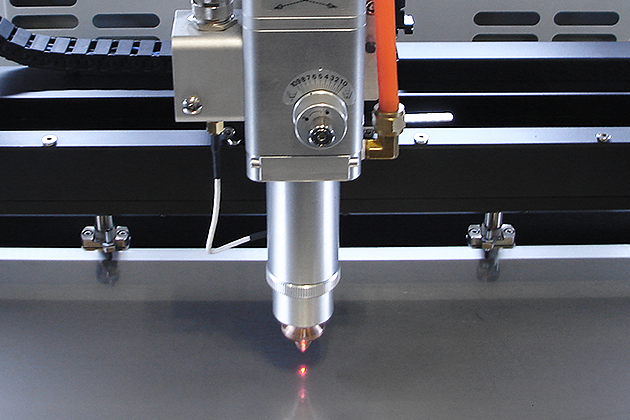

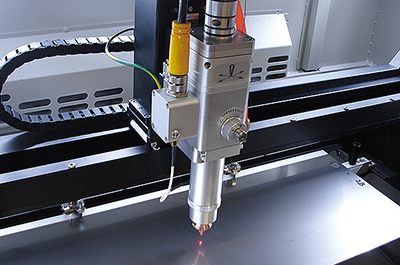

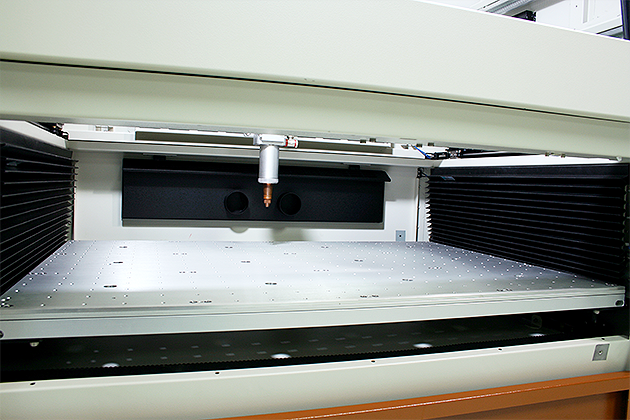

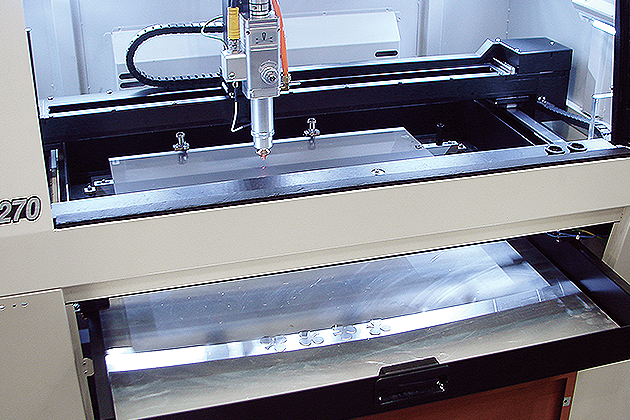

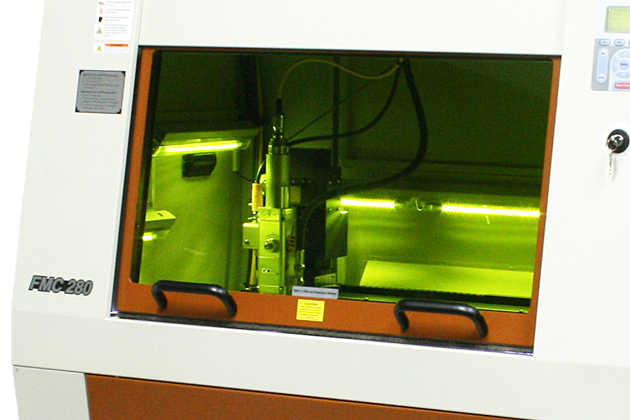

Unique Fiber Laser Source with Exquisite Cutting Capability

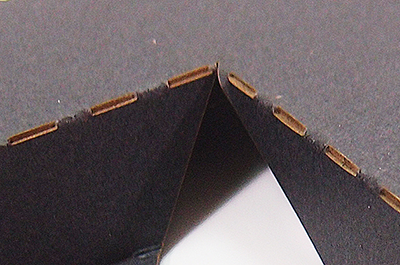

World leading fiber laser source with unique laser firing mode control meets variety metal sheets processing demand. Powerful cutting capability to handle up to 3mm thick stainless steel and high reflective metals (aluminum, copper) with clear edge now possible.

– For USB storage (Max. 32GB capacity, FAT file system)

– For USB storage (Max. 32GB capacity, FAT file system)  – For connecting with the computer

– For connecting with the computer