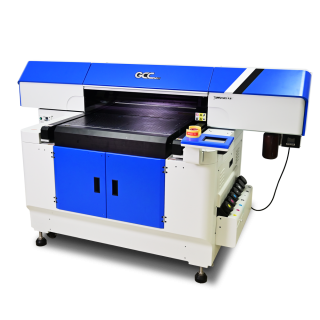

🆕 JF-2418UV Inkjet Printer

| GCC Laser Engraving and Cutting Machines

English

Showcase Video

Applicable Models

-

-

🆕 StellarMark 3DS 20-50W Fiber Laser Marker

🆕 StellarMark 3DS 20-50W Fiber Laser Marker -

JF-240UV Inkjet Printer

JF-240UV Inkjet Printer -

StellarMark C-series 12-30W CO2 Laser Marker

StellarMark C-series 12-30W CO2 Laser Marker -

StellarMark I-series 20-60W Fiber Laser Marker

StellarMark I-series 20-60W Fiber Laser Marker -

LabelExpress Laser Finisher

LabelExpress Laser Finisher -

X252 80-100W CO2 Laser Cutter

X252 80-100W CO2 Laser Cutter -

i-Craft™ 2.0 Desktop Vinyl Cutter

i-Craft™ 2.0 Desktop Vinyl Cutter -

S400 Dual Laser System Laser Engraver

S400 Dual Laser System Laser Engraver -

DecalExpress Laser Finisher

DecalExpress Laser Finisher -

X380 80-100W CO2 Laser Cutter

X380 80-100W CO2 Laser Cutter -

Spirit GLS Hybrid CO2 Fiber Laser Engraver

Spirit GLS Hybrid CO2 Fiber Laser Engraver -

AR-24 Small Vinyl Cutter

AR-24 Small Vinyl Cutter -

🆕 X500III Pro 100-150W CO2 Laser Cutter

🆕 X500III Pro 100-150W CO2 Laser Cutter -

DecalExpress-ECO Laser Finisher

DecalExpress-ECO Laser Finisher -

Spirit LS 12-100W CO2 Laser Engraver

Spirit LS 12-100W CO2 Laser Engraver -

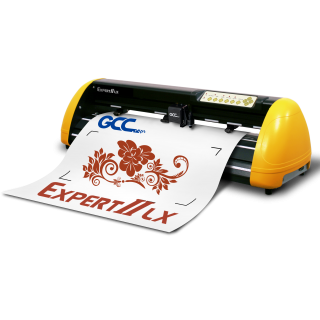

Expert II Vinyl Cutter

Expert II Vinyl Cutter -

FMC 280 1.5KW Fiber Laser Cutter

FMC 280 1.5KW Fiber Laser Cutter -

C180II 12-40W CO2 Desktop Laser Engraver

C180II 12-40W CO2 Desktop Laser Engraver -

Puma IV Vinyl Cutter

Puma IV Vinyl Cutter -

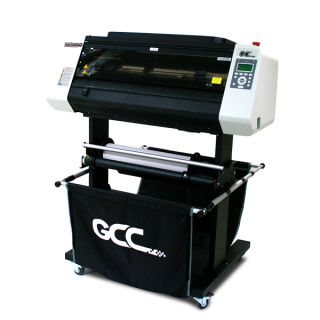

AFR-24S Automatic Finisher

AFR-24S Automatic Finisher -

🆕 LFC II Laser Marker Workstation

🆕 LFC II Laser Marker Workstation -

T500 60-200W CO2 Laser Cutter

T500 60-200W CO2 Laser Cutter -

Spirit 12-100W CO2 Laser Engraver

Spirit 12-100W CO2 Laser Engraver -

Jaguar V Vinyl Cutter

Jaguar V Vinyl Cutter -

🆕 E200 40W CO2 Desktop Laser Engraver

🆕 E200 40W CO2 Desktop Laser Engraver -

RX II / RX II (Creasing) Vinyl Cutter

RX II / RX II (Creasing) Vinyl Cutter -

S290LS 20-60W Fiber Laser Engraver

S290LS 20-60W Fiber Laser Engraver -

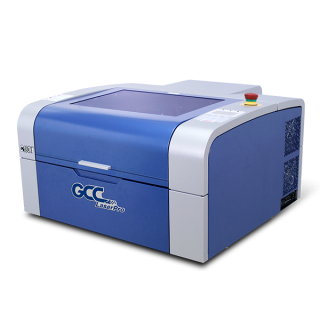

Mercury III 12-80W CO2 Laser Engraver

Mercury III 12-80W CO2 Laser Engraver -

JV-240UV Varnish Printer

JV-240UV Varnish Printer -

MG380Hybrid 12-100W CO2 Laser Engraver

MG380Hybrid 12-100W CO2 Laser Engraver -

MG380Hybrid 12-100W CO2 Laser Cutter

MG380Hybrid 12-100W CO2 Laser Cutter