Printable Flex Heat Transferring with GCC Cutting Plotters | GCC Laser Engraving and Cutting Machines

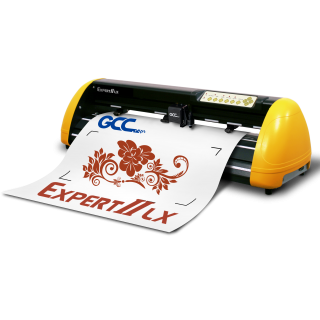

Flex is excellent for textile heat transferring as it is highly flexible and tender with exceptional elongation and perfectly adhests to the textile with cracking-free capability. This film shows you how to heat-transfer an image on Flex to a T-shirt. A GCC Cutting Plotter, an Eco-Solvent Printer, a Heat Press Machine and some Flex is all you need to complete a customized T-shirt full of fun and creativity.

Step 1

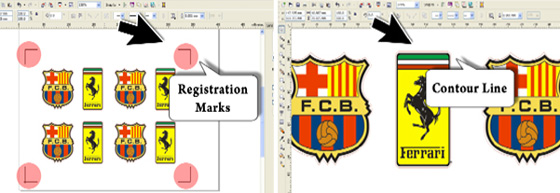

Create an image with a contour line and registration marks on CorelDraw/ Illustrator and print it out on a heat transfer printable flex by an eco-solvent printer.

Step 2.

Cut your image using a GCC cutting plotter.

Step 3. Firmly fix the printable flex on the heat transfer backing and remove the backing.

Step 4. Place a Teflon sheet over the T-shirt and press the heat transfer backing with the printed image on the T-shirt using a heat press machine at 150℃ for 15 seconds.

Now you have a customized T-shirt for yourself, or friends and families.

Parameters:

| Speed | 60 |

| Force | 75 |

| Offset | 0.275 |

| Quality | Normal |

| Heat transfer temperature | 130°C |

| Heat transfer time | 15 |