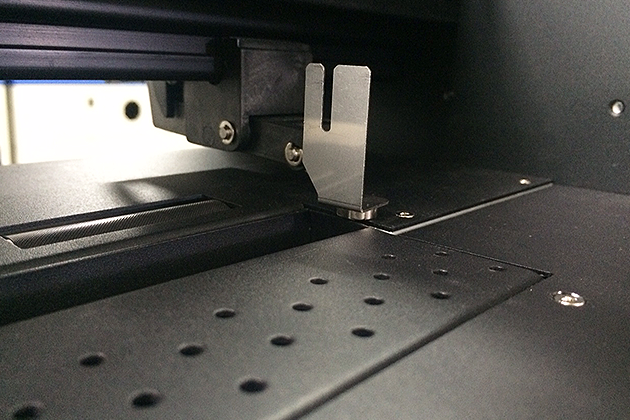

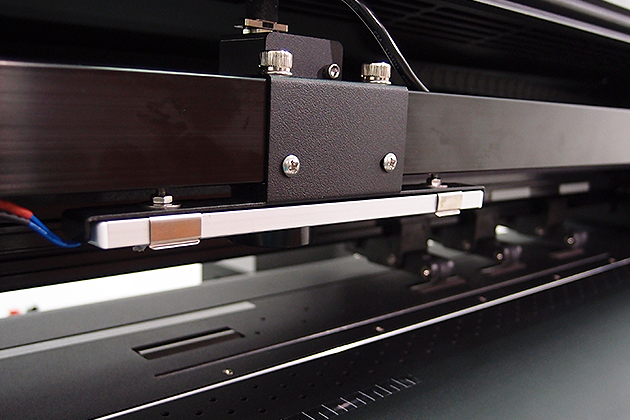

Waste Drawer

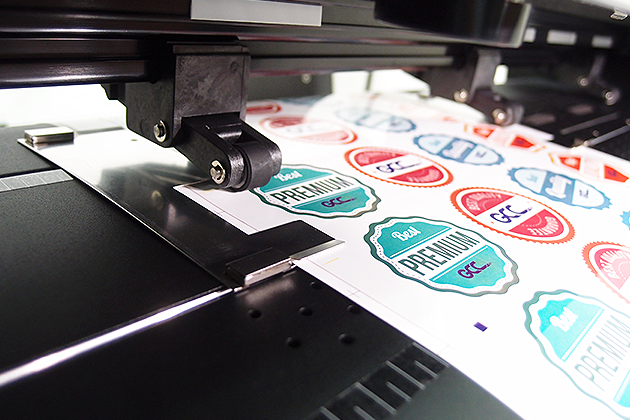

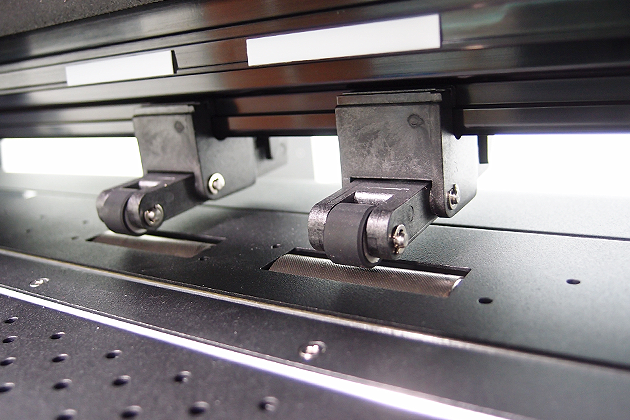

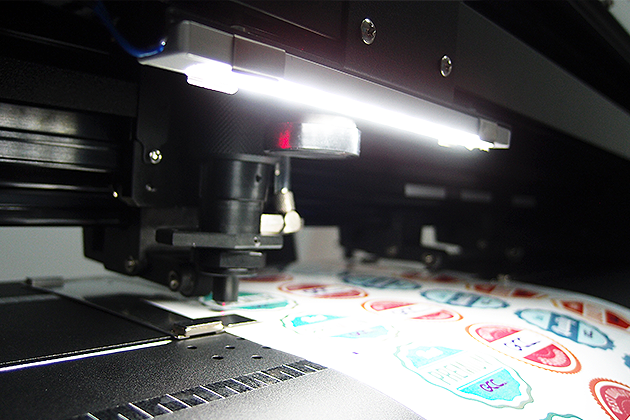

The Waste collects unnecessary materials when performing cut through function providing an uninterrupted workflow. Media Support Brackets that is pre-installed on the work area is able to hold the media and keep the media flat while moving back and forth.