Laser Engraving and Cutting on Plastics | GCC: Laser Machines Leader Since 1989

Laser engraving and cutting technologies have revolutionized manufacturing and design across a variety of industries. With the right laser system, plastics can be engraved, cut, or marked with high accuracy and permanent results, all without damaging the material. Compared to traditional methods, laser processing delivers cleaner details, greater design flexibility, and long-lasting quality. This article explores the fascinating world of laser engraving, cutting and marking on plastics—how it works, what materials are suitable, and why it might be the perfect solution for your specific needs.

IG:@profilprisma

How Plastic Laser Engravers Work?

Explanation of Laser Engraving on Plastic

Laser engraving on plastic involves using focused laser energy to vaporize or remove portions of the material surface. The intense heat generated by the laser beam causes the plastic to either melt, burn, or vaporize, creating a depression or cavity in the material. This process creates highly visible, permanent marks that resist wear and environmental factors.

Types of Plastics Suitable for Laser Engraving

Many plastics respond well to laser engraving, especially those with stable chemical structures. Common laser-friendly plastics include:

-

PMMA (Polymethyl Methacrylate), also known as acrylic, is clear, affordable, and easy to process. It’s widely used as a glass substitute, especially in signage and advertising.

-

ABS (Acrylonitrile Butadiene Styrene) is strong and impact-resistant, commonly used for TV shells, washing machine panels, and refrigerator drawers.

-

PET (Polyethylene Terephthalate) is the material used for mineral water and soda bottles due to its strength and clarity.

-

POM (Polyoxymethylene) is tough and rigid, often used for mechanical parts and engineering components.

-

PC (Polycarbonate) is transparent with moderate heat resistance, used in phone cases, laptop covers, and CDs/DVDs.

While many plastics can be effectively processed with lasers, we recommend conducting material tests beforehand to ensure optimal results. Additionally, certain plastics, such as PVC, may release hazardous fumes during laser processing. Always ensure adequate ventilation and consider using a fume extraction system for a safer working environment.

Please note: The fiber laser cannot engrave or cut transparent plastic materials.

Types of Lasers Used

-

CO2 Lasers:

CO₂ lasers are ideal for engraving and cutting plastic materials like acrylic, ABS, and polycarbonate. With power levels from 30W to 150W, they provide clean cuts, smooth edges, and deep engravings at a cost-effective rate—also well-suited for large-format applications.

-

Fiber Lasers:

Fiber lasers excel at marking engineered plastics and additive-filled polymers. Operating at 20W to 100W+, they offer high precision, fine detail, and crisp, high-contrast markings through surface color change, rather than deep engraving—ideal for logos, serials, and QR codes.

One thing to note is that color change from fiber laser processing depends on the plastic’s composition.

Advantages of Laser Engraving on Plastic

Permanent and Durable Marks

Laser marking integrates directly into the material, ensuring long-lasting, wear-resistant results that withstand chemicals and environmental factors.

Non-Contact and Stress-Free Processing

The laser operates without physical contact, preventing mechanical stress or deformation—ideal for delicate or pre-assembled components.

High Precision and Speed

Capable of producing intricate details, barcodes, QR codes, serial numbers, and complex logos with exceptional accuracy, even on small parts.

Flexible and Cost-Effective

Digital workflows allow quick design changes without tooling costs, making laser marking ideal for customization, variable data, and short production runs.

Eco-Friendly and Clean Process

No inks, chemicals, or consumables are required, reducing waste and making it a sustainable marking solution.

Versatile Across Industries

Suitable for applications in automotive, electronics, medical devices, and more, meeting diverse marking needs.

@creartech

Laser Techniques for Plastic

Engraving

Laser engraving uses focused laser energy to quickly create permanent marks on plastic with low power consumption. Depending on the laser source, it can produce either high-contrast marks or deep engraving, suitable for barcodes, serial numbers, and logos.

Cutting

Laser cutting fully penetrates plastic to separate it into precise shapes. Using a focused laser beam, it melts or vaporizes material to create clean edges. Ideal for signage, prototyping, and enclosures, it offers speed, flexibility, and handles complex designs better than traditional cutting.

Marking

Laser marking, on the other hand, alters the surface of the plastic without significant material removal. It commonly relies on color change, carbonization to produce visible marks. These effects are achieved by precisely controlling the laser’s parameters—such as speed, frequency, and energy density—to trigger localized chemical or structural changes in the material. Marking is ideal for barcodes, logos, and decorative elements where surface integrity must be maintained.

Color change

Another way to add color to acrylic is ‘Powder Coating Coloring’. Simply apply the powder coating material to the desired area and proceed with the engraving—no masking or weeding needed, and it’s easy to clean up afterward.

Fields of application

-

Transportation and Mobility: Including automotive parts, aerospace interiors, marine components, and public transit structures.

-

Architecture and Construction: Decorative elements, panels, and structural plastic features used in buildings.

-

Energy and Sustainability: Components in renewable energy systems, such as insulators and panel mounts.

-

Lifestyle and Recreation: Gear and accessories for sports, leisure, and hobbies, plus model-making and prototypes.

-

Home and Sanitation: Plastic elements in bathrooms and sanitary installations.

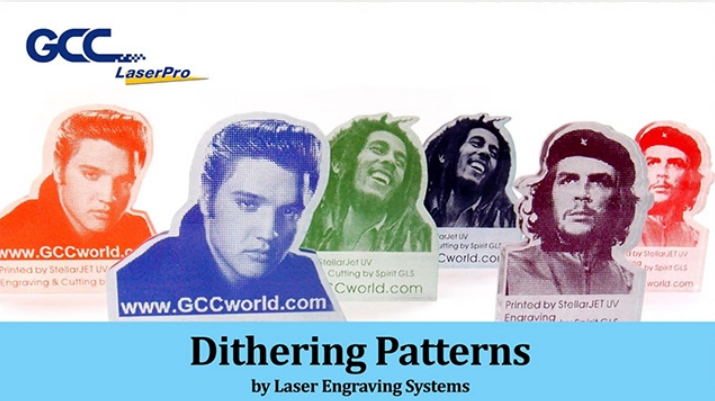

Plastic materials can be transformed into eye-catching creations—turning everyday objects into one-of-a-kind gifts for friends and family. Looking for ideas? Explore our Sample Gallery to discover the endless possibilities of laser engraving on plastic! With a GCC LaserPro laser engraver, you too can bring your creative visions to life.

Why Use GCC Machines for Plastic Laser Engraving and Cutting?

GCC offers a range of laser systems designed to handle plastic engraving and cutting with precision and efficiency. Here are some top recommendations:

Piolas 400 Laser Engraver

The Piolas 400 delivers high productivity with 175 IPS speed and a spacious 40”×24” work area. Equipped with SmartEYES™ CCD for precise positioning and live-view alignment, it’s perfect for both personalization and mass production. Ideal for plastic engraving and cutting—clean edges, high accuracy, and efficiency.

Spirit GLS Hybrid PRO Laser Engraver

The Spirit GLS Hybrid PRO features dual-laser technology optimized for plastic processing, enabling high-speed engraving, cutting, and marking. In addition to non-metal materials, it can also process metals. SmartEYE™ CCD and the optional SmartVISION Elite CCD ensure precision and versatility for demanding tasks.

E200S Series

The E200S Series is a professional-grade CO2 desktop laser engraver designed for ease of use, stability, and precision. Equipped with a closed-loop DC servo motor, it delivers accurate, repeatable results and smooth motion—especially for acrylic engraving and cutting. Ideal for educational use and small businesses seeking reliable, high-quality performance.

Laser engraving and cutting on plastics continue to evolve as technology advances. From simple serial numbers to intricate designs, from one-off prototypes to high-volume production, laser technology offers unmatched versatility for processing plastic materials. By understanding the principles, techniques, and equipment options outlined in this article, you can make informed decisions about implementing laser marking in your specific application.