We are pleased to interview Erden Takenov, owner of GCC partner Alma Distribution Ltd and Director General of PPF film distribution/installation service provider Gmask Kazakhstan. He will share his success story as a case study that will help inspire others in the laser and vinyl cutting machine applications and the automotive industry.

Company Name: Alma Distribution Ltd, Gmask Kazakhstan Ltd

Major Business Items: Supply automotive detailing materials and tools, automotive vinyl films, and protective films.

Location: Almaty, Kazakhstan

Website│Instagram│Facebook

GCC Products: GCC LaserPro Spirit GLS Hybrid 40W laser engraver, GCC RX II -183S vinyl cutter

GCC products takes jobs to the next level

Established in 2010, Gmask Kazakhstan began its journey as a distributor of car wrapping films, quickly adapting to the burgeoning Paint Protection Film (PPF) market in partnership with Xpel, a renowned PPF film and patterns designer. Our early venture into PPF was met with a significant challenge: the use of a low-quality, no-name plotter led to considerable material wastage, spoiling expensive PPF films due to the plotter's inaccuracies and poor performance.

This pivotal experience in 2011 compelled us to search for a high-quality plotter, leading us to discover GCC. Recognizing GCC's unmatched quality and the absence of a local distributor, we seized the opportunity and established Alma Distribution Ltd, becoming the exclusive distributor of GCC in Kazakhstan.

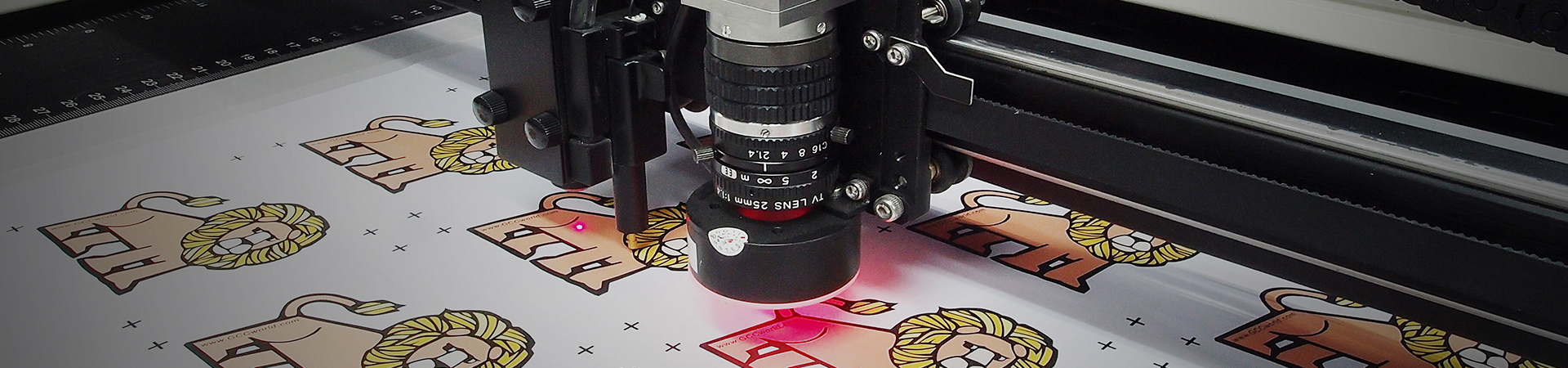

Since then, Gmask Kazakhstan has grown substantially. We are now a major supplier of PPF films throughout Kazakhstan, offering PPF precut kits to installers and car dealerships. Our office boasts three advanced GCC RX183 plotters, and we have been instrumental in providing GCC plotters to other PPF installers nationwide. In 2023, we expanded our offerings by introducing the GCC LaserPro Spirit laser engraving machine for precision cutting of static screen protection films for car displays, a specialized product requiring meticulous laser cutting. Our dedication to overcoming challenges with quality solutions has solidified our position as a leader in the automotive protection and customization industry in Kazakhstan.

Displaying GCC RX II vinyl cutters

The main reasons for choosing to introduce GCC products

I've encountered a particularly challenging situation in my business. Initially, we used a low-quality, no-name plotter for cutting Paint Protection Films (PPF). Unfortunately, this plotter proved to be highly unreliable, leading to the destruction of a significant amount of expensive PPF material due to its inaccuracies and subpar performance. This experience was a turning point for me. It drove me to thoroughly research and find the best quality plotter available to ensure precision and efficiency in our work.

We entrust GCC vinyl cutter with the task of cutting PPF films and Static Display protection films. The machine's efficiency in handling these materials is unparalleled, ensuring precise cuts every time. But it's not just about its functionality; it's about the seamless integration into our workflow. This machine becomes an indispensable part of our process, enhancing efficiency and productivity. The reason for choosing GCC lies in its reliable and straightforward design. These machines are easy to maintain and repair, allowing users to handle various issues effortlessly. Whether it’s efficient production line operations or day-to-day tasks, GCC’s design ensures smooth performance.

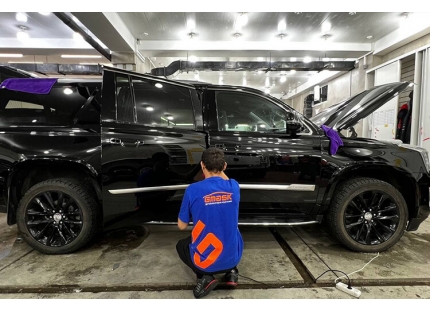

Paint Protection Film is used for automotive detailing

Benefits of using GCC products

The introduction of GCC products has had a profoundly positive influence on both the operational efficiency and profitability of our business. One of the most significant benefits we've experienced is the consistent reliability of these machines. Unlike some of our competitors who have faced extensive downtime, sometimes lasting almost a month due to waiting for parts for their plotters, we've encountered no such issues with our GCC plotters. They are always operational and remarkably easy to use. This reliability means we can maintain a steady workflow without interruptions, directly contributing to our profitability and giving us a competitive edge in the market.

The most important aspect of GCC products for our business is their exceptional reliability. This reliability ensures consistent machine uptime, allowing us to meet deadlines and maintain high-quality standards without interruption. It translates to operational efficiency, reduced downtime, and decreased material wastage, directly enhancing our profitability. Additionally, the dependability of GCC products bolsters our reputation in the competitive automotive customization market, attracting clients who value professionalism and precision. In essence, GCC's reliability is not just about smooth operations; it's a key driver of our business growth and customer satisfaction.

Pre-cut film makes the job easier to execute

Future plans and prospects

In the future, I aim to further expand our capabilities by adding an additional cutting plotter to our office. This new plotter will be specifically dedicated to cutting car window tinting films, allowing us to broaden our service offerings and meet the growing demands of our customers. This expansion reflects our commitment to continually evolving and enhancing our business to better serve the automotive customization market.

Indeed, expanding our business and venturing into new sectors is a key part of our strategy, underpinned by the capabilities of GCC products. In addition to investing in a 3D scanner in 2023 for developing custom PPF patterns, we are also embarking on an ambitious project to create our own PPF patterns cutting software. This software have to be compatible with GCC plotters, adding value to our offerings and providing our customers with an integrated, user-friendly solution for their PPF cutting needs. This innovation, coupled with our plan to establish a branch in Canada, represents our commitment to not just expanding our geographic footprint, but also enhancing the technological aspect of our services. The synergy of our advanced technology and GCC's reliable equipment will play a pivotal role in both our domestic and international growth.

Introduced laser engraving machine:

We are happy to answer your questions about any laser products and processing. If you want to learn and do more with GCC LaserPro lasers, we invite you to see our laser engraving and cutting applications videos where you will find out how they physically work and are done.

Further reading:

➤Discover the Power of Laser Engraving

➤Exploring the Versatility of Laser Engraving: Capabilities and Materials

➤SmartEYES™ CCD is Your Time-Saving Tool to Boost Productivity